What Is LCD Conditioning?: LCD (Liquid Crystal Display) conditioning is a term you may have heard of but not fully understood. It’s not just a buzzword thrown around in the tech industry, it’s actually quite important for ensuring your LCD displays are working properly. Whether you’re using an LCD monitor or television in your home, understanding LCD conditioning is vital for maintaining and prolonging the life of your display. This blog post will discuss exactly what LCD conditioning is and how it can be used to ensure that your LCD displays are functioning optimally and lasting longer.

What is LCD Conditioning?

Table of Contents

LCD conditioning is the process of prepping a liquid crystal display (LCD) screen for use. This step helps protect the screen from permanent damage caused by burn-in marks or ghost images.

Burn-in marks are caused by prolonged viewing of static images that cause liquid crystals to become stuck in one position and result in permanent discoloration on the screen.

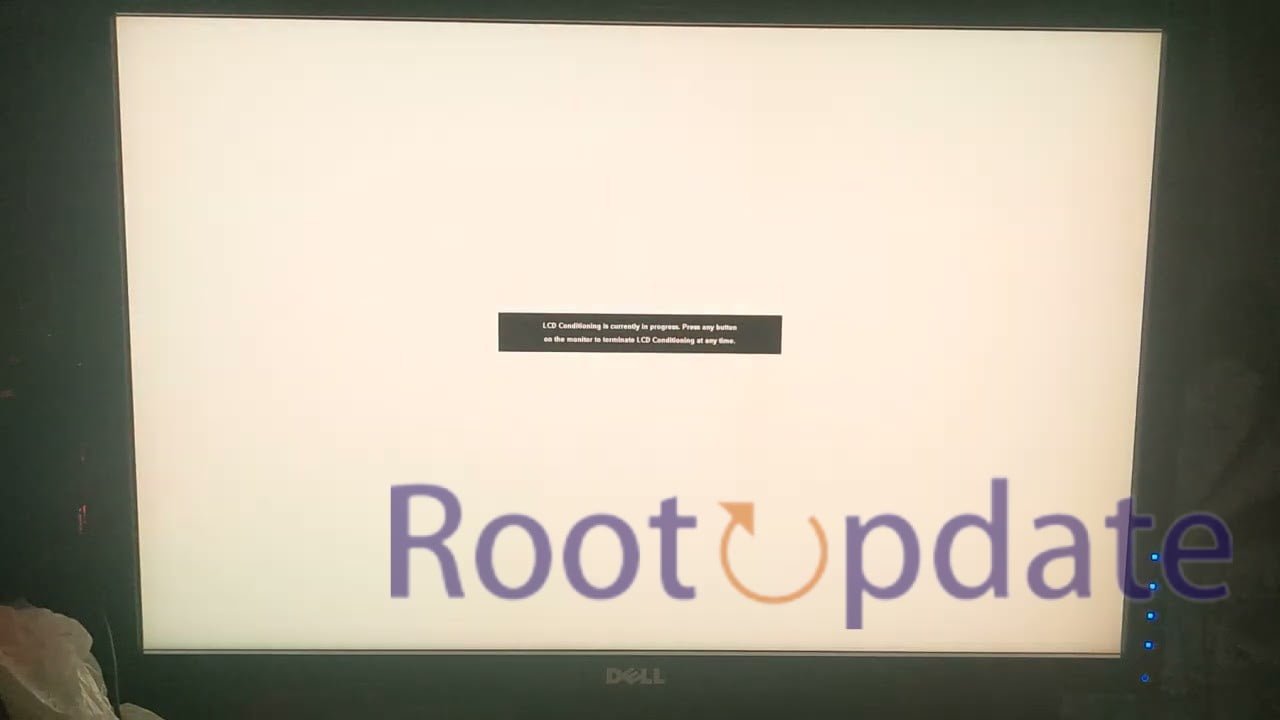

LCD conditioning involves displaying a series of moving images, white screens and color screens to “exercise” the liquid crystals and reduce the risk of burn-in marks.

Typically, this step is completed during the manufacturing of an LCD panel; however, it can also be completed by the user if needed.

What Is LCD Conditioning?

— Harsh Chauhan (@iammHarsh) February 9, 2024

LCD Conditioning Basics

An LCD, or liquid crystal display, is a type of display device that utilizes liquid crystals to produce images. Liquid crystals are unique materials in that they can transform their properties when exposed to an electric field – this explains how LCDs use them for controlling light transmission.

LCDs consist of two layers: the front layer and the back layer. The front contains liquid crystals, while the back contains a material called a polarizer. These two components are separated by a thin piece of glass, leading to LCDs being referred to as “thin-film transistors” (TFTs).

When no voltage is applied to an LCD display, its liquid crystals remain in their “relaxed” state. This means they allow light to pass through them evenly, creating an image with dark colors. When voltage is applied however, these crystals change their orientation so some light is blocked off – creating areas of darkness and light which can be used to create visual interest in an image.

LCDs can be classified as positive or negative. Positive LCDs feature dark pixels and clear backgrounds, while negative LCDs have clear pixels with dark backgrounds. Nowadays, most LCDs are positive because they use less power and produce sharper images when displaying images with darker colors.

LCD conditioning is a process used to prepare liquid crystal display (LCD) screens for use and reduce the risk of permanent damage caused by burn-in marks or ghost images.

LCD conditioning involves displaying a series of moving images, white screens and color screens to “exercise” the liquid crystals and reduce the risk of burn-in marks.

Conditioning an LCD panel is usually part of the manufacturing process, but can also be completed by the user if desired.

It should be noted that the web search results referred to multiple subjects with the same name, each discussing a different aspect of LCD technology – not specifically LCD conditioning.

LCD Conditioning Tools

LCD conditioning tools are used to enhance the visual appeal of LCDs. They can be used to remove scratches, smudges and fingerprints as well as protect them from future damage.

LCD (Liquid Crystal Display) conditioning tools are used to prepare LCD displays, especially after storage or shipping. The purpose of conditioning is to help the liquid crystals within the display reach a stable state and deliver consistent image quality.

There are various LCD conditioning tools available, such as:

- Burn-in Images: Burn-in images are static pictures displayed on a computer screen for an extended period of time to help stabilize liquid crystals.

- Break-in Videos: Break-in videos are dynamic images displayed on a screen for an extended period of time to help liquid crystals settle into their stable state.

- Backlight Aging: Backlight ageing refers to the process of running an LCD display at a high backlight level for an extended period, in order to help the backlight reach stability and reduce brightness and colour shifts over time.

It is essential to be aware that LCD conditioning is usually only necessary for high-end displays and is not generally applicable to most consumer-grade LCDs. Furthermore, some manufacturers may have specific conditioning requirements so it’s always best to consult the manufacturer’s documentation for guidance.

The Different Types of LCD Conditioning

LCD conditioning comes in four varieties: off-delay, on-delay, flashing and scrolling.

Off-delay refers to when the LCD turns off for a specified period before turning back on, while on-delay occurs when it stays turned on for an extended period before switching back off. Flashing refers to when the LCD turns on quickly and off rapidly; scrolling describes when text or images on the screen scroll across it.

Pros and Cons of LCD Conditioning

LCD conditioning is a method used to enhance the visual appeal of LCD screens. It involves applying an appropriate solution and then buffing it with a soft cloth. This helps remove any smudges or fingerprints on the display while making it appear brighter and more vibrant.

LCD conditioning can have both positive and negative effects. On one hand, it improves your screen’s overall aesthetic appeal; if yours is older, this could make it look brighter and newer. Furthermore, LCD conditioning helps protect against scratches and other damages by shielding the display from scratches.

However, LCD conditioning has its drawbacks as well. One major drawback is the time commitment it requires – if you have a hectic schedule, conditioning your screen on a regular basis may become impossible. Furthermore, failing to properly condition it could actually damage it over time.

Alternatives to LCD Conditioning

When it comes to LCD conditioning, there are a few alternatives you can select from. For instance, an LED screen may be more energy-efficient than LCDs and offer better picture quality too. An OLED alternative would also work great if you want your screen to last for years.

Related:

Conclusion

LCD conditioning is an effective way to extend the life of your LCD display. By following the steps outlined in this article, you can ensure optimal performance and picture quality from your display. With regular maintenance, your LCD will look just as bright and beautiful as when it first came out of the box!